Stainless steel fabrication

For pet food and animal feed industries

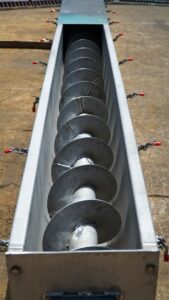

For the animal feed industry, our bespoke stainless steel fabrication services are adept at manufacturing a diverse range of equipment and machinery. This includes storage tanks, silos, stainless steel tanks, support structures for stainless steel conveyor belts, and stainless steel screw conveyors.

Stainless steel fabrication

For food and food processing industries

In the food and food processing industry, tanks and pipes are commonly employed in industrial buildings. We offer stainless steel fabrication services tailored to meet customer requirements, encompassing the production of storage tanks, stainless steel silos, cones, industrial pipes, validation pipes, as well as dust collector pipes.

Stainless steel fabrication

For industrial buildings

For industrial customers, we provide a full range of custom stainless steel fabrication services. This encompasses industrial pipes, validation pipes, dust collector pipes, duct pipes, various types of tanks, conveyor belt supports, and screw conveyors.

Stainless steel fabrication

For structural construction

The applications of stainless steel fabrication are extensive across various industries and structural construction, due to its lightweight and rust-resistant characteristics. Our services extend to the fabrication of structures, including stainless steel roof structures for parking lots, structures for vinyl roofs, and various other stainless steel applications.

Stainless steel fabrication

For architectural construction

To meet customers’ architectural stainless steel fabrication needs, we offer services for manufacturing stainless steel door frames, window frames, spiral staircases, handrails, railings, and decorative materials for indoor and outdoor spaces.

Request for a Quotation

Why choose our custom stainless steel fabrication services?

With our expertise, we offer tailored raw material sourcing services for your industrial applications. Customers can request raw material certificates, enabling verification of material origins, grades, and quality directly from the manufacturing company, ensuring strict adherence to specifications. Additionally, we provide 2D and 3D design services for stainless steel fabrication, catering to customers with ideas but without production drawings. As a full-service stainless steel fabricator, we offer cutting, bending, rolling, welding, and assembling. Entrusting Eurica Technology and Supply ensures centralized access to a range of services—all conveniently located in one place to meet your specific stainless steel fabrication needs.

Raw material sourcing services

For workpieces demanding specific-grade raw materials in industrial applications, such as food-grade 304 stainless steel for the food industry, we provide high-quality sourcing services tailored to your specifications. Additionally, customers can request information about steel manufacturers and raw material certificates. (upon customer request)

Design services for stainless steel fabrication

Whether you require stainless steel tanks or pipes, with or without production drawings, we provide 2D/3D design services using CAD or 3D simulation systems. If you already have your own design, we seamlessly proceed to the manufacturing process.

Stainless steel cut, bend, and roll services

Whether your workpieces involve tanks, pipes, or stainless steel cut-and-bend processes, our services cover the entire manufacturing process. This includes utilizing high-precision CNC machines for cutting and bending stainless steel workpieces, ensuring bend allowance and bend radius adhere to designs. We also offer rolling services for stainless steel pipes and tanks, employing advanced 3-roll and 4-roll bending machines capable of handling a diverse range of sizes and shapes.

Pipes, tanks, and, custom stainless steel welding services

After cutting and rolling, our one-stop stainless steel fabrication includes welding services for tanks, pipes, and various workpieces. We use electric, CO2, and argon welding machines selected for specific workpieces, accommodating variations in thickness across different stainless steel components.

Quality inspection services for custom stainless steel fabrication

We provide quality inspection services for custom stainless fabrication, both during and after the production process. Our meticulous approach ensures precision in width, as well as radius of bend and roll, guaranteeing that welding lines exhibit both aesthetic appeal and durability. Customers can confidently entrust us with high-quality and standardized workpieces.