Steel cutting and bending services

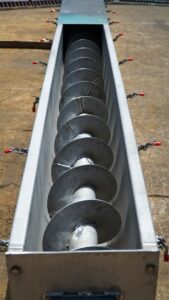

For pet food & animal feed industries

From rolling steel workpieces, cones, industrial pipes, and custom tanks to assembling, our comprehensive services cover a wide range of applications in the animal feed industry.

Steel cutting and bending services

For food and food processing industries

Our steel cutting and metal forming services support the production of various equipment and tools for the food and food processing industries, such as silos. These silos are designed to store a variety of food products, preventing moisture, air, and contaminants.

Steel cutting and bending services

For structural construction industry

For structural construction, our steel cutting and bending services excel in producing an array of components, including garage structures, steel structures, roof structures, parking roof structures, solar panel mounting rails, aluminium solar mounting rails, as well as expertly bending angle steel bars and steel beams.

Steel cutting and bending services

For industrial buildings

Our facility is capable of cutting and bending for various applications, including ventilation pipes, industrial dust collector pipes, pipes for industrial buildings, steel pipes, duct pipes, and dampers.

Steel cutting and bending services

For architectural construction industry

In our fully equipped factory, we offer comprehensive steel cutting and bending services tailored for architectural construction applications. These encompass composite facades, aluminium composite facades, window frames, spiral stairs, steel stairs, steel handrails, building envelopes, and decorative facades.

Request for a quotation

Why choose us for your steel cutting

and bending projects?

As a steel fabrication specialist, Eurica offers high-quality raw materials sourcing services tailored to meet your industry-specific requirements. Customers can request raw material certificates, providing verification of material origin, material grade, and quality of stainless steel from manufacturers. This ensures that the raw materials align precisely with the specified requirements. Additionally, in our commitment to comprehensive steel fabrication services, we provide 2D/3D design services for stainless steel workpieces. This is particularly beneficial for customers without their own production drawing ideas. Our steel cut and bend solutions cover every aspect of the process, from cutting and bending to rolling, welding, and assembling. Regardless of the steel workpieces involved, Eurica Technology and Supply is equipped to handle all aspects of the service, providing a one-stop solution for your needs.

Design services for steel cutting and bending workpieces

For customers without their own production drawings or those with basic sketches, we offer 2D and 3D production drawing design services using CAD or 3D simulation systems. Conversely, if customers already have their own 2D/3D designs, we efficiently proceed with the manufacturing of your customized workpieces.

Raw material sourcing services

If customers have specific raw material specifications, we offer raw material sourcing services for cut and bend workpieces that align with their requirements and applications in various industries. Whether it’s the raw material grade, material origin, or manufacturing company, or if customers request raw material certificates, we promptly coordinate to ensure that the raw materials meet their precise requirements.

High-precision steel cutting and bending services

We offer cutting and bending services for steel and metal. Our advanced machines have the capability to cut and bend according to specific designs using computer programs. This includes cutting steel plates, custom steel fabrication, angle steel bars fabrication, metal plate fabrication, laser cutting, steel cutting, and hole punching, all tailored to meet your unique needs.

Metal forming and welding services

After completing the steel and metal cutting and bending process, we extend our services to include rolling and welding. This allows us to assemble customized workpieces using 3-roll and 4-roll plate bending machines, which can handle large metal plates with a maximum thickness of 25 mm. Our welding services employ electric welding machines, CO2 welding machines, or argon welding machines, operated by specialists to ensure that the welding lines of each workpiece are not only aesthetically pleasing but also robust.

Quality inspection of steel cutting and bending workpieces

Throughout the entire production process, we conduct thorough quality inspections of the steel and metal workpieces. This includes verifying if the workpieces align with the design specifications. For the inside part of workpieces bent at multiple points, we need to strictly inspect the accuracy of the bend allowance at every point, ensuring the space of each point adheres to the design. Our commitment to high precision and accuracy is evident in our continuous attention to bend allowance inspection of steel workpieces.

Fast and on-time delivery

By utilizing high-precision and capable machines controlled by CNC systems, we manufacture steel workpieces quickly and precisely, minimizing errors and ensuring on-time delivery.